Manufacturing Technology Trends

When 2019 came to a close, we reached the end of a decade in which much changed on the technology front. In 2010, smartphones were on the cusp of becoming ubiquitous, DVDs were still the preferred way to watch a movie at home and the idea of ordering a device in your home to control the lights, temperature and music was still more sci-fi than reality. Today, we all carry a tiny computer around in our pockets, streaming video continues to flourish, and home assistants are increasingly common — and powerful.

As we look at the manufacturing trends 2020 will bring, it’s worth a quick examination of the common thread running through all these advances. Major technological changes like these are, at their core, a matter of convenience. People want to do the same things they’ve been doing — watch movies, check email, adjust the temperature — and these advances make it that much easier and convenient.

Manufacturing trends for 2020 and beyond will come from a similar place, though “convenience” may not be quite the right word. The end products of manufacturing aren’t going to vastly change, but the way in which they are produced will continue to change and evolve, eventually becoming unrecognizable compared to practices used even 20 or 30 years ago. Here are some trends to watch out for in 2020.

Manufacturing Trends, 2020 and Beyond

1. Industry 4.0 gains footholds

Industry 4.0 remains a popular topic when discussing the current and future state of manufacturing, and it will continue to make inroads in 2020. But don’t expect full adoption over the next 12 months.

Industry 4.0 comprises many things, but is generally considered to involve the use of big data and automation to create efficiencies in processes. A full implementation of Industry 4.0 equipment and practices is a huge capital commitment, but these technologies will slowly make their way into more and more facilities, forcing others to follow in order to remain competitive.

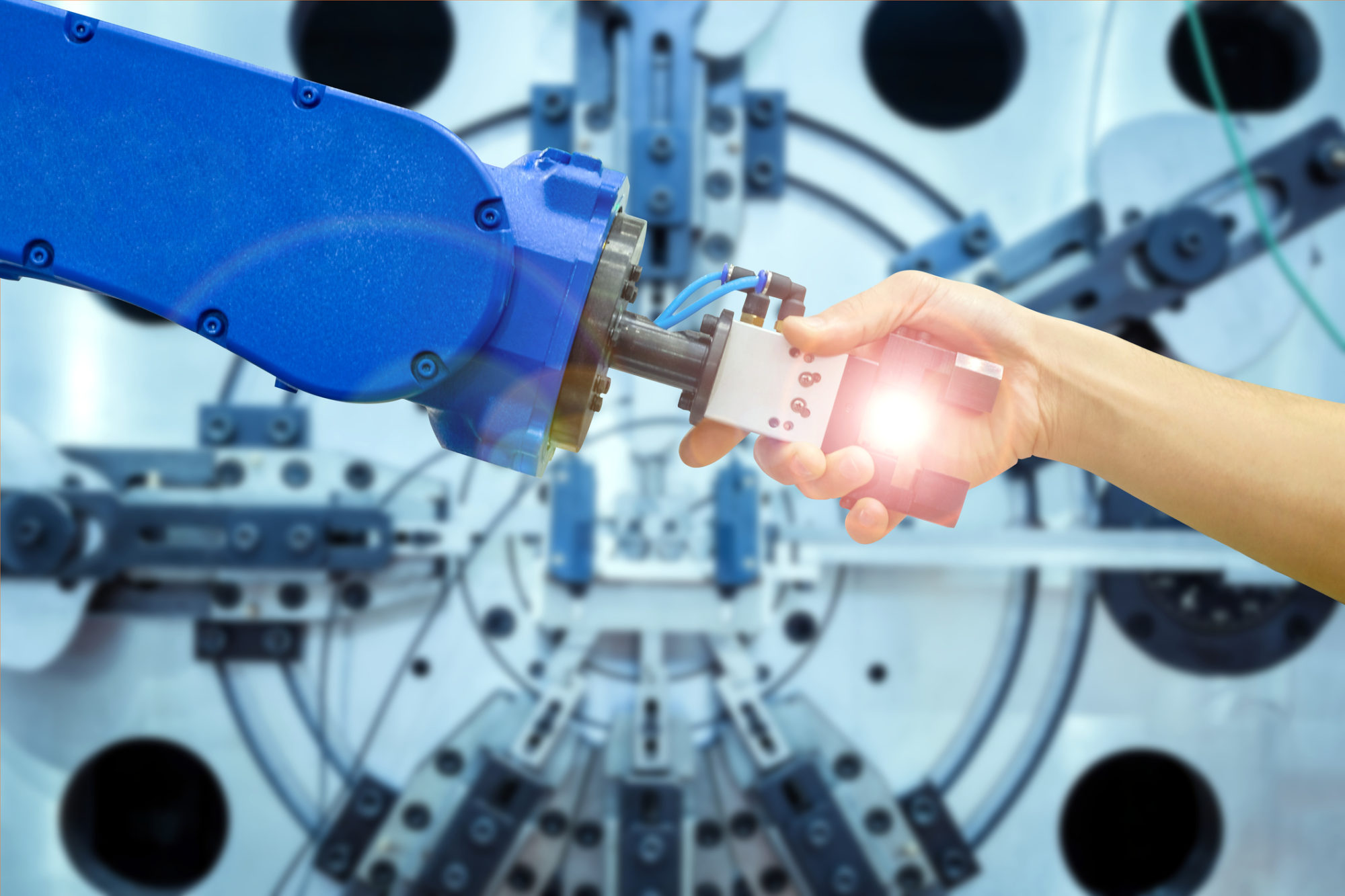

2. More helping hands from robots

Robots in the manufacturing setting are nothing new – but as they become smarter, safer and more mobile, the industry will see their use grow. Inventory, assembly and machining become increasingly efficient as robots are able to do more and provide greater benefit to their human co-workers.

3. Wearable tech

Following the shift to handhelds, the next step in on-demand data and information will be wearable devices. Smart watches, headsets with heads-up displays and other wearables will provide critical data more quickly and unobtrusively than ever.

4. Increased focus on customer service

While customer service has always been a major priority for successful manufacturers, the continued integration of technology with manufacturing will make it even more important. As data collection and monitoring tools of Industry 4.0 become more commonplace, customers will have more visibility into production status via dashboards and other tools. With this increased visibility will come with a push for ever-improving performance and quality — a win for all involved.

5.VR and AR

Virtual reality and augmented reality are finally beginning to realize the promise they have advertised for years. These technologies will impact areas like training and maintenance in various ways, including:

- “Hands-on” training — Training and testing can be carried out in a VR environment, creating a much safer and lower-risk process.

- Remote maintenance — Much like arthroscopic surgery done remotely via camera, augmented reality will allow for maintenance technicians to carry out procedures from a remote location, making great strides toward closing the skills gap and improving efficiency.

- Greater control over processes — Both VR and AR can yield greater efficiency, improved accuracy and more targeted, predictive maintenance by providing more visibility and insight into processes as they occur.

6. Still the skills gap

Although VR and AR can mend a small area of the skills gap, it will remain an issue across industry. As processes and requirements change, it’s important for current and future workers to be well versed in the evolving tools of the trade, including 3D printing, 3D scanning, robotics, and other IIoT practices and tools.

7. Cybersecurity

Cybersecurity is a looming concern for every industry, and manufacturing is no exception. As connected devices and machines become the norm, vulnerability to cyber intrusions grows. It’s important for manufacturers to be aware of these risks as they adapt their facilities to the processes of today and the future.

While implementing even a few of these trending technologies can help improve the efficiency and output of your facility overall, their capabilities can significantly benefit your industrial maintenance practices. Looking to improve your maintenance strategy and stay ahead of the competition? Contact us today to learn more.